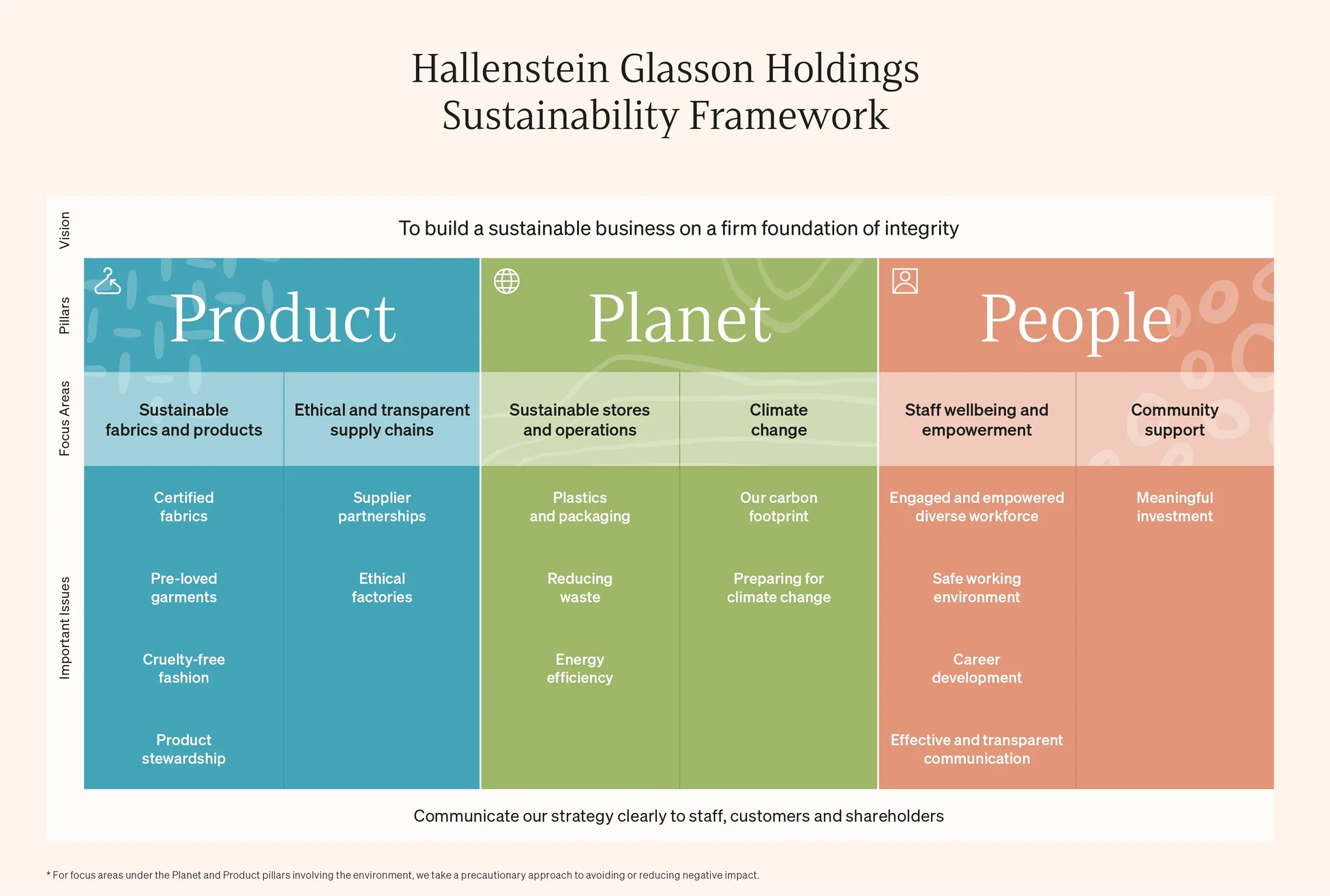

In 2020 we started reporting on our sustainability journey and shared our sustainability commitment - Made with Care.

Made with Care is our pledge to bring affordable fashion to our customers as ethically and sustainably as we possibly can - it applies to the life cycle of every fashion garment; from the fabrics we use, how it's made and supplied, how we package it, upcycle it, and how we can minimise waste at the end of its life.

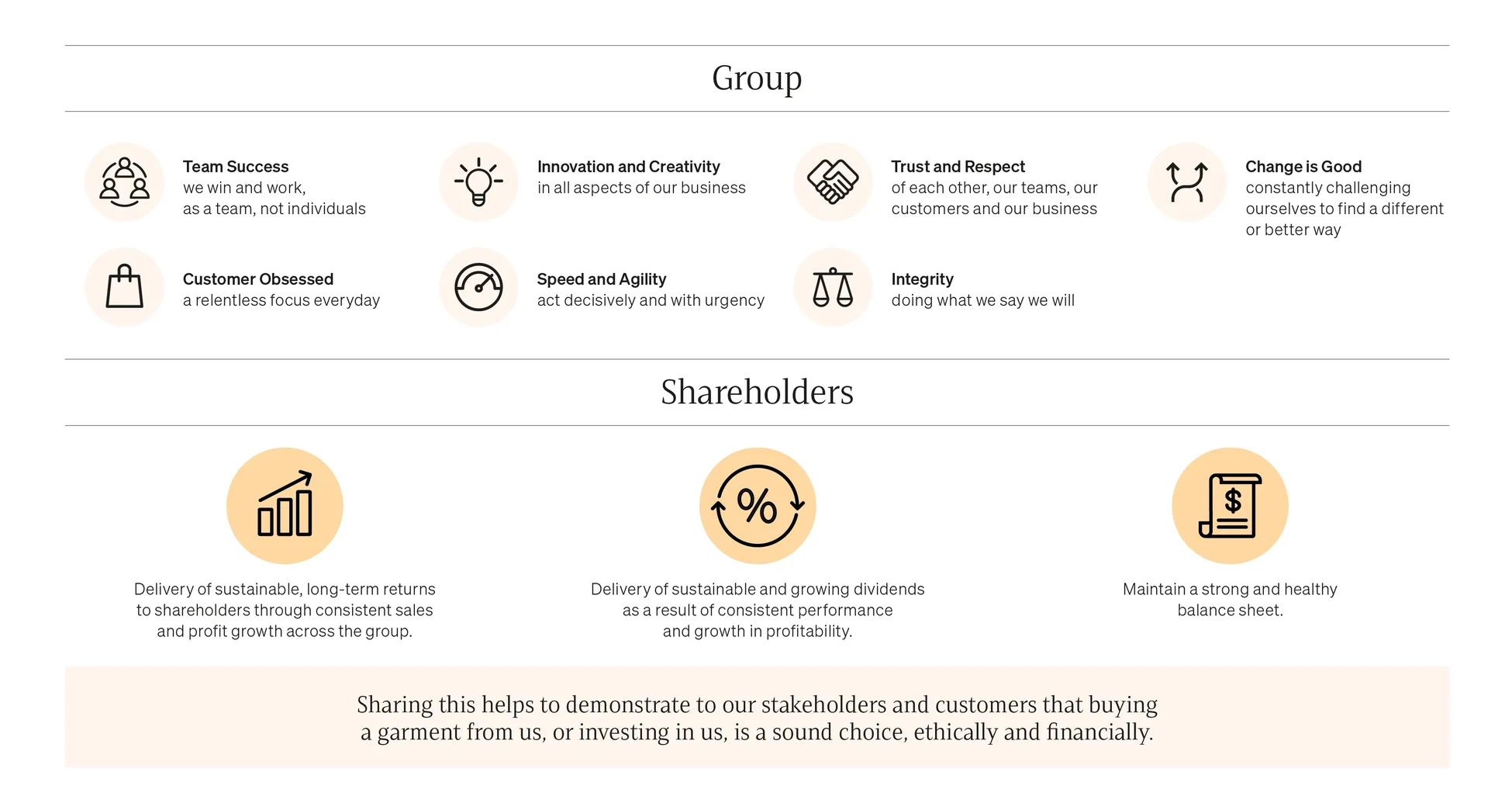

There's always more we can do and wherever possible, we'll continue to improve sustainability and visibility in all areas of our operation, so our stakeholders and our customers can see what we've done, how we've improved and what we have planned to minimise HGH's environmental impact on the planet and be a force for good